Our Bottle Series

In this guide, we will teach you everything you need to know about stainless steel water bottle! We will discuss including its composition, material, process, technology, size, packaging, pricing, the different types of stainless steel flasks available, how to choose the right one, and how to use it safely. Let’s get started!

Wide Mouth Series

Bottle Size

For wide mouth water bottle, we have the most popular 6 kinds of sizes: 12oz, 18oz, 24oz, 32oz, 40oz and 64oz. From the 12oz to 40oz, just the bottle’s height is different, other’s part are all the same. And 64oz has two kinds of shape, the only difference is the neck. You can choose the short neck or the long neck.

Bottle Lids

The wide mouth water bottles can be matched with a wide range of lids, generally divided into: handle lid, flip lid, straw lid and stainless steel lid. Most of them are made of BPA free plastic, a few are made of stainless steel.

Both the handle lid and the stainless steel lid have a handle, which makes it easy to carry on the go, and you need to unscrew the lid when drinking.

The flip lid has a handle on some models and not on others, also it’s easy to drink from, just open the flip-top piece on the lid.

The straw lid always comes with a straw, which is placed inside the bottle, so you don’t need to open the lid when drinking, just open the spout part of the lid and you can drink. Nowadays there are a few models of straw lids with a handle, so that it is easy to drink and easy to carry by hand.

Narrow Mouth Series

Bottle Size

For narrow mouth water bottle, we have the most popular 4 kinds of sizes: 350ml(12oz), 500ml(18oz), 600ml(21oz) and 750ml(27oz). From the 12oz to 27oz, just the bottle’s height is different, other’s part are all the same.

The mouths of all capacity narrow bottles are the same size, so all lid styles are suitable.

Bottle Lids

The narrow mouth water bottles can be matched with a wide range of lids, generally divided into: handle lid, straw lid, bamboo lid and stainless steel lid.

Most of the lids have a handle, which makes it easy to carry on the go, and you need to unscrew the lid when drinking.

The straw lid always comes with a straw, which is placed inside the bottle, so you don’t need to open the lid when drinking, just open the spout part of the lid and you can drink.

Some stainless steel lid’s components can be matched with bamboo, which looks beautiful and stylish. Many customers choose this style, but the price is a little more expensive compared to plastic lids.

Single Wall Growler

Most customers prefer to choose this single wall beer growler in silver color and spray paint color with a customized logo, such as silk screen printing, laser engraving and other technologies. Some customers also like to do gas transfer printing, where the whole growler is printed all over, which is very nice.

This growler is quite large, so customers also like to match it with a cloth bag, which can be carried by hand or on the back, suitable for going out.

Double Wall Growler

The beer growler is one of the insulated bottles, double-layered stainless steel and vacuum insulated. This growler is made of 304 stainless steel both inside and outside. Between the double stainless steel is an insulating layer, with the machine to pull out the air from this layer, to achieve a vacuum state, then the bottle can be filled with hot or cold water.

There is only one lid to match this growler, which is basically done in black, with a few customers choosing to do it in other colors. The lid has a handle to make it easy to carry outside by hand, perfect for outdoor use.

For this kind of beer growler, we have 3 kinds of sizes: 18oz, 36oz, and 64oz. These three capacities have the same size of the mouth, only the diameter of the bottom and the growler’s height are different. If you want to make other capacities, you can only open a mould for it. Most customers do not choose to open mould and these three capacities already meet the basic needs.

Cola Bottle Series: Styles & Size

The Cola bottles can be divided into four styles, each style has its own characteristics.

Style 1: This is the most regular and best-selling style.

Style 2: This style has a flat base and a slightly altered lid and mouth, which will look particularly different from the style 1.

Style 3: This style has the same base as the style 1, the body is in the narrow mouth series and all the lids on this Cola bottle are from the same range as the narrow mouth series.

Style 4: This is the most unusual style because its body can be divided in two. The lower part of the bottle is vacuum insulated and the upper part of the lid is equipped with a carrying loop for easy carrying. This style is the most complex and expensive one.

The cola water bottle totally has 4 sizes: 260ml, 500ml, 750ml and 1000ml. And the most popular size is 500ml, most of clients prefer to choose this size.

style 1

style 2

style 3

style 4

Single Wall Bottle Sizes

A lot of client prefer single wall water bottles with non-vacuum and we can see this bottle everywhere in the market. Depending on the customer’s needs, can choose 304 stainless steel or 201.

We generally have 2 styles of single wall water bottles: narrow mouth bottle with top diameter 4.5cm and wide mouth bottle with top diameter 5.5cm. The diameter of the mouth and bottom of the wide mouth bottles are larger than the diameter of the narrow mouth bottles.

Narrow mouth bottles are available in five sizes: 350ml, 500ml, 600ml, 750ml and 800ml. And wide mouth bottles are available in two sizes: 2L and 2.4L.

Single Wall Bottle Lids

The single wall water bottles can be matched with a wide range of lids, generally divided into: plastic lid and stainless steel lid. Most of them are made of BPA free plastic, a few are made of stainless steel.

The stainless steel lid always come with a handle, which makes it easy to carry on the go.

For plastic lid, several kinds are straw lid always comes with a straw, which is placed inside the bottle, so you don’t need to open the lid when drinking, just open the spout part of the lid and you can drink.

Bouncing Thermos

The bouncing thermos is one of the insulated thermos, double-layered stainless steel and vacuum insulated. This thermos has a 304 stainless steel liner and the shell can be 304 or 201, depending on the customer’s needs.

Pull down the insurance buckle, press the botton, cover pops up the entire process antomatically with one hand to complete your drinking water heeds anytime, anywhere.

Straight Thermos

We have several straight thermos styles, most of which contain tea leaks and are perfect for office workers.

Some of them have a lid with a temperature indicator so that you can see the temperature of the water as soon as it is poured in. Some of them have a small flip-top lid, so you don’t need to unscrew the lid, just open the flip-top then you can drink.

straight thermos style 1

temperature straight thermos style 2

straight thermos style 3

straight thermos style 4

More Styles Thermos

Other Popular Icobottles

If you are looking for a bottle that can keep your drinks cool or warm, we have just the thing. You’ll find vacuum bottles in all shapes and sizes so no matter what kind of drinker you may be, there’s an option here!

We are very strict in producing our products, going through several processes from the transportation of raw materials to the processing of the finished products. We want to ensure that every hip flask you receive is 100% in good quality.

Bottle Package

Egg Grid

This is the cheapest packaging way, save space and cost.

White Box

Most client choose this kind of packaging, cheaper and save.

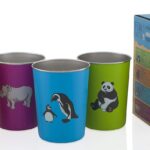

Color Box

Some client prefer this packaging, upscale and beautiful.

Display Box

This packaging is suitable for supermarkets, aesthetically pleasing.

Bottle Technologies

There are 5 most common logo technologies for water bottles: silk screen printing, laser engraved, electroplating, gas transfer, heat transfer and 3D printing.

Laser engraved: Not only can the logo be engraved on the body of the bottle, but many customers prefer to engraved on the bottom and lid of the bottle. The darker the paint, the better the engraved will look. Lighter colored bottles are less suitable for engraved. If the order is small, engraved is a good option. The Labor cost is determined by the length of the engraved time. The larger the pattern, the longer the engraved time, the higher the charge. the laser on the powder coating is actually with a laser to knock down the coating layer, revealing the color of stainless steel, forming a logo pattern. Engraved on the coating is more difficult than on spray paint, because the surface of powder coating is harder, then much longer engraved time, the price will also be much more expensive.

Gas transfer: some clients like to print colorful patterns, then can choose this technology. The gas transfer process is generally divided into the following steps: 1. spray the whole bottle with a white lacquer, dry it and then spray a transparent lacquer; 2. wrap the whole bottle with printed patterned paper, wrap it as tightly as possible to facilitate the transfer of the pattern on the bottle; 3. put the bottle into the oven and adjust the specific temperature and time for baking; 4. after baking, wait for the bottle to cool down, tear off the paper outside and you can see the pattern printed on the surface of the bottle.

Silk screen printing: This technology is the most common, simple and beautiful to produce. Also the ink color can be customized, as long as the pantone color code is provided, the closest color can be printed on the growler’s surface.

Heat transfer: The bottles are first spray paint with a lacquer, as the top half of the bottle is curved and cannot be printed, so the colored pattern can only be printed on the bottom half of the bottle. Heat transfer only can be done on spray paint surface, can’t do on powder coating.

3D printing: This technology has not been around for long and is a new one. It can be printed in multi-color, and when finished, the design is three-dimensional and has a convex feel when touched by hand. The whole bottle will look very stylish and upscale.

Bottle Colors

The water bottles can be spray painted or powder coating, most customers prefer to have it powder coating. There are so many off-the-shelf coating colors to choose from, the most common being black and white, as well as the usual blue, red, purple and yellow colors. Many customers also prefer to have custom colors, just the minimum order quantity is a little higher.

Multi-color coating is also a popular style now, with 2 or 3 colors for one bottle. If the colors are well matched, the whole bottle will look very classy, especially for travelling or hiking, and will look great in your hand.

Frequently Asked Questions

What is the minimum MOQ of water bottle?

Bottle’s minimum MOQ depends on its styles. Some can do lower MOQ like 500pcs or 1000pcs, some need 3000pcs. If some kind we have in stock, 100pcs or 200pcs we also can provide.

What is the lead time of bottle order?

Almost need 25-30days if customized order. Sometimes if we have blank in stock, lead time can be much shorter.

Can I request a free bottle sample?

It depends on bottle’s price. If the bottle you want in stock and cheaper unit price, we can offer free sample, you just pay the express cost. If sample customized, contact saler to get the sample cost.

Can we use our own logo or design for sticker?

Yes, you can. You can contact with the salesmen. Pls send an email to her/him and tell more details.

Can I make a new shape water bottle?

You can send me the design drawing first, we will see if the new shape bottle can be done or not. If design no problem, we will send you full quotation with open mould cost soon.

How to know my logo use which kind technology?

After we see your logo picture, we already know which technology is better to do your logo with the most economical way.

Request A Free Quote

Product Categories

ManufacturingProcess

Cute Pipe

Body Forming

Cleaning

Welding

Polishing

Leak Testing

Customized Logo

Packaging

Benefit From Your Committed Bottle Manufacturer

Strong ODM & OEM Ability

Our experienced design and engineering team can develop custom water bottle solutions from concept to production. We offer comprehensive ODM services including product design, mold development, and prototype creation, as well as flexible OEM manufacturing to meet your specific requirements.

Quality Management System

Our ISO 9001 certified quality management system ensures consistent excellence in every product. From raw material inspection to final quality control, we maintain strict standards throughout the manufacturing process, providing you with reliable, high-quality water bottles every time.

Quality Assurance

Every bottle under goes comprehensive testing including leak testing, insulation performance testing, and durability assessments. Our quality assurance team conducts thorough inspections at multiple check points to guarantee that only products meeting our premium standards reach our customers.

Free Water Bottle Sample

Experience our quality firsthand with complimentary samples. We provide free samples of our standard products so you can evaluate the quality, design, and functionality before placing your order. This allows you to make informed decisions and ensures complete satisfaction with your purchase.

Ready to Start Your Custom Water Bottle Project?

Custom Stainless Steel & Insulated Water Bottles for Wholesale Buyers

Custom Caps/Lids

The wide mouth water bottles can be matched with a wide range of lids, generally divided into: handle lid, flip lid, straw lid and stainless steel lid. Most of them are made of BPA free plastic, a few are made of stainless steel.

Both the handle lid and the stainless steel lid have a handle, which makes it easy to carry on the go, and you need to unscrew the lid when drinking.

The flip lid has a handle on some models and not on others, also it’s easy to drink from, just open the flip-top piece on the lid.

The straw lid always comes with a straw, which is placed inside the bottle, so you don’t need to open the lid when drinking, just open the spout part of the lid and you can drink. Nowadays there are a few models of straw lids with a handle, so that it is easy to drink and easy to carry by hand.

. Flip-top and push-pull designs

. Straw and sport cap options

. Custom color matching available

. BPA-free food-grade materials

Custom Capacities

We offer a comprehensive range of capacity options from 12oz to 64oz to meet diverse market needs. Whether you need compact bottles for corporate gifts or large capacity bottles for outdoor enthusiasts, we can manufacture bottles in your preferred size with consistent quality and performance.

. 12oz - 20oz: Compact and portable

. 24oz - 32oz: Standard daily use

. 40oz - 64oz: Large capacity options

. Custom sizes available upon request

Custom Package Box

Enhance your product presentation with custom packaging solutions.We offer gift boxes, retail packaging, and bulk shipping boxes designed to protect your products and reinforce your brand identity. All packaging can be customized with your logo, colors, and marketing messages.

. Premium gift box packaging

. Retail-ready display boxes

. Eco-friendly packaging options

. Custom branding and design

Custom Colors

The water bottles can be spray painted or powder coating, most customers prefer to have it powder coating. There are so many off-the-shelf coating colors to choose from, the most common being black and white, as well as the usual blue, red, purple and yellow colors. Many customers also prefer to have custom colors, just the minimum order quantity is a little higher.

Multi-color coating is also a popular style now, with 2 or 3 colors for one bottle. If the colors are well matched, the whole bottle will look very classy, especially for travelling or hiking, and will look great in your hand.

. Pantone color matching available

. Gradient and ombre effects

. Metallic and special effect finishes

. Color-fast and fade-resistant

Bottle Technologies

There are 5 most common logo technologies for water bottles: silk screen printing, laser engraved, electroplating, gas transfer, heat transfer and 3D printing.

Laser engraved: Not only can the logo be engraved on the body of the bottle, but many customers prefer to engraved on the bottom and lid of the bottle. The darker the paint, the better the engraved will look. Lighter colored bottles are less suitable for engraved. If the order is small, engraved is a good option. The Labor cost is determined by the length of the engraved time. The larger the pattern, the longer the engraved time, the higher the charge. the laser on the powder coating is actually with a laser to knock down the coating layer, revealing the color of stainless steel, forming a logo pattern. Engraved on the coating is more difficult than on spray paint, because the surface of powder coating is harder, then much longer engraved time, the price will also be much more expensive.

Gas transfer: some clients like to print colorful patterns, then can choose this technology. The gas transfer process is generally divided into the following steps: 1. spray the whole bottle with a white lacquer, dry it and then spray a transparent lacquer; 2. wrap the whole bottle with printed patterned paper, wrap it as tightly as possible to facilitate the transfer of the pattern on the bottle; 3. put the bottle into the oven and adjust the specific temperature and time for baking; 4. after baking, wait for the bottle to cool down, tear off the paper outside and you can see the pattern printed on the surface of the bottle.

Silk screen printing: This technology is the most common, simple and beautiful to produce. Also the ink color can be customized, as long as the pantone color code is provided, the closest color can be printed on the growler’s surface.

Heat transfer: The bottles are first spray paint with a lacquer, as the top half of the bottle is curved and cannot be printed, so the colored pattern can only be printed on the bottom half of the bottle. Heat transfer only can be done on spray paint surface, can’t do on powder coating.

3D printing: This technology has not been around for long and is a new one. It can be printed in multi-color, and when finished, the design is three-dimensional and has a convex feel when touched by hand. The whole bottle will look very stylish and upscale.

Use Cases & Applications

Corporate Gifts

Promotional Items

Retail Products

Sports Teams

Events & Conferences

Hospitality Industry

Custom Shape Water Bottle Mold Tooling Processes

tailored to your specifications

Design & Engineering

Our expert team creates detailed CAD drawings and 3D models based on your specifications, ensuring optimal functionality and aesthetics.

Mold Creation

Precision molds are crafted using high-grade steel with CNC machining for consistent wall thickness and perfect shape retention.

Material Selection

Premium 18/8 stainless steel sourced from certified suppliers, ensuring food safety and durability standards.

Deep Drawing Process

Advanced deep drawing techniques shape the stainless steel into perfect tumbler forms with uniform wall thickness.

Vacuum Insulation

Double-wall construction with vacuum insulation technology maintains temperature for extended periods.

Surface Treatment

Professional polishing, powder coating, or custom color application for superior finish and branding.

Quality Control

Rigorous testing for leak-proof performance, temperature retention, and durability under various conditions.

Custom Branding

Laser engraving, screen printing, or embossing of your logo with precision placement and lasting durability.

Packaging & Shipping

Professional packaging with custom inserts and reliable logistics to North America and European markets.

Frequently Asked Questions

Get Your Custom Quote

will contact you within 24 hours.