Are glass-lined flasks viable? Pros, cons, and breakage risk in shipping

I used to receive calls from buyers asking about glass-lined flasks. They wanted something premium-looking. But then the shipments arrived damaged. The returns started piling up. I realized glass creates more problems than it solves.

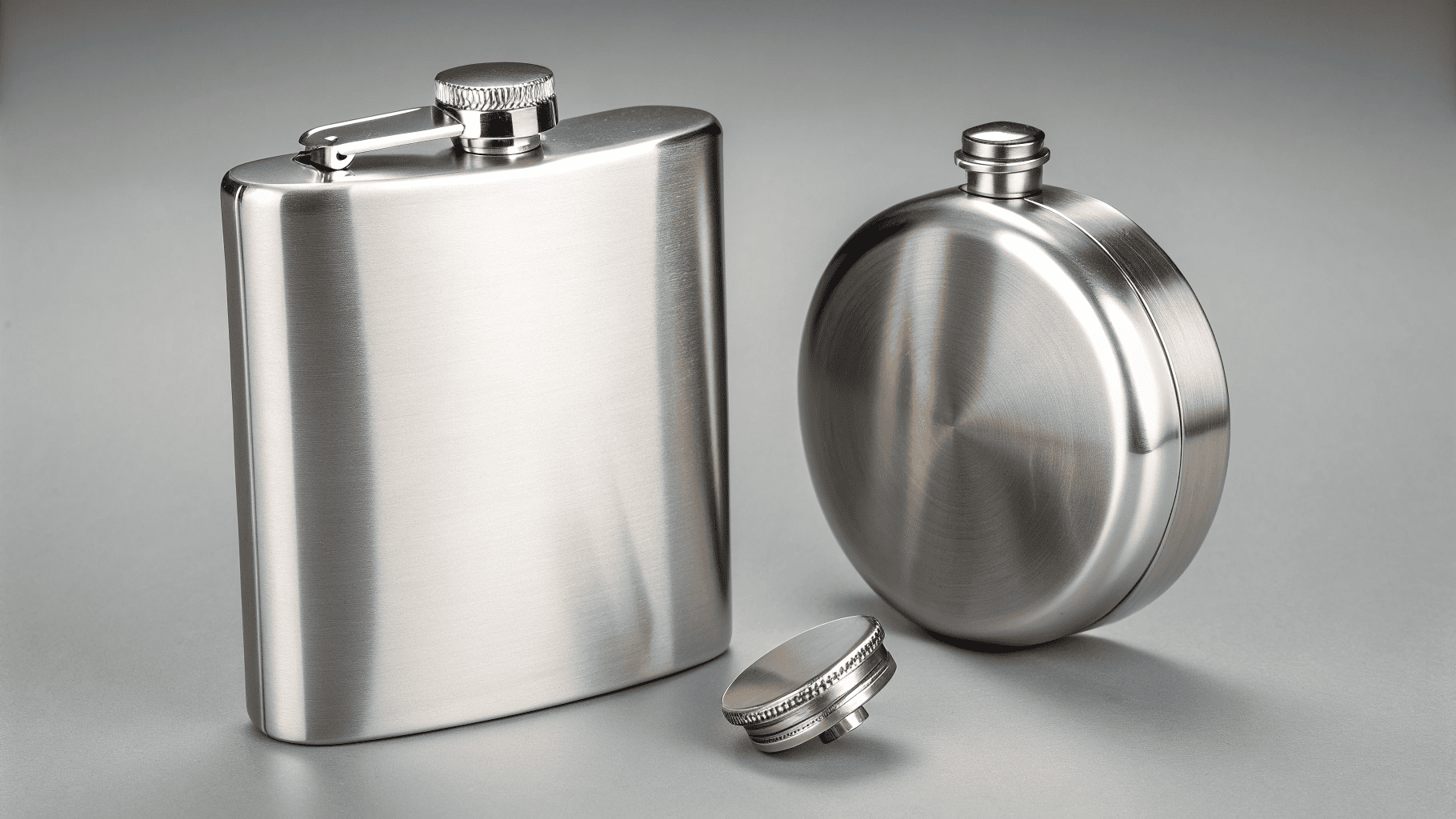

Glass-lined flasks carry high breakage risk during shipping. The material requires expensive protective packaging1. Modern buyers prefer stainless steel alternatives that offer better durability and lower total costs. For B2B operations2, glass simply doesn't make practical sense anymore.

I've been in this business long enough to see the shift happen. When I started at Icobottle, some clients still requested glass options. Now almost everyone comes to me asking for stainless steel water bottles or tumblers. The reason is simple. Glass breaks. When it breaks during shipping, everyone loses money. The supplier loses. The buyer loses. The end customer gets disappointed.

How to keep glass from breaking during shipping?

I remember one order where we tried every protection method available. We used bubble wrap. We added foam corners. We placed each flask in a separate compartment. The breakage rate still hit 8%. That's when I understood glass needs more than just careful packaging.

Preventing glass breakage requires multiple layers of protection and significantly increases shipping costs. You need egg crates, custom foam inserts, and reinforced outer cartons. Even with these measures, breakage remains a persistent risk that impacts your bottom line.

The packaging requirements for glass make it impractical for large orders. I work with buyers who order 5,000 to 10,000 units at a time. Let me break down what glass packaging actually means. First, you need individual protective sleeves for each unit. Then you need internal dividers in the carton. The cartons themselves must be double-walled. You also need corner protectors and top-bottom cushioning.

| Protection Layer | Cost Per Unit | Weight Addition |

|---|---|---|

| Individual sleeve | $0.15 | 20g |

| Divider system | $0.08 | 35g |

| Double-wall carton | $0.25 | 180g |

| Corner protectors | $0.05 | 15g |

| Cushioning material | $0.12 | 45g |

| Total | $0.65 | 295g |

This table shows the real cost. But it doesn't show the dimensional weight penalties. Carriers charge based on space, not just weight. Glass packaging takes up much more space than our standard cylinder boxes for stainless steel bottles. I've seen shipping costs double just because of the packaging volume. The other issue is handling. Every person who touches the package needs to treat it as fragile. This slows down warehouse operations. It increases labor costs. It creates bottlenecks during peak seasons.

What is the major disadvantage of glass as a packaging material?

I had a client from Texas who insisted on glass bottles for a corporate gift program. We shipped 3,000 units. By the time they cleared customs and reached his warehouse, 240 bottles had broken. The glass shards damaged another 180 bottles. He couldn't use almost 15% of his order. That's when he asked me about stainless steel options.

Glass carries multiple critical disadvantages in commercial operations. It's fragile during logistics. It requires complex and expensive protective packaging. It increases dimensional weight charges. It creates potential liability issues if breakage causes injuries. The material simply doesn't align with modern supply chain requirements.

Let me explain why we switched our focus to stainless steel at Icobottle. The material performance difference is dramatic. Our 304 stainless steel water bottles can survive a 1.5 meter drop test without damage. Glass can't. We can ship stainless steel bottles in standard white boxes with minimal foam padding. The packaging cost drops to about $0.10 per unit. The weight addition is only about 50 grams.

There's another disadvantage that buyers often overlook. Glass limits customization options. You can't do laser engraving easily. Powder coating is impossible. Screen printing works but the durability is poor. With stainless steel, I can offer laser engraving, powder coating in any Pantone color, silk screen printing, and even hydro dipping. One of my Canadian clients rebrands bottles with his own logo and color scheme. He needs consistent quality and multiple finish options. Glass can't deliver that flexibility.

The return logistics present another problem. If a glass bottle arrives broken, the buyer needs to document it with photos. They need to dispose of the broken glass safely. The replacement unit needs the same expensive packaging. The entire process costs time and money. With stainless steel, damage during shipping is rare. When it happens, the bottle usually just has a minor dent. Most buyers accept it or we replace it quickly.

Are glass flasks safe?

I remember a buyer who stopped ordering glass after an incident at a trade show. One of his samples broke in a customer's hand. The cut required stitches. He faced potential liability. He switched to stainless steel immediately. Safety isn't just about meeting standards. It's about eliminating unnecessary risks.

Glass flasks meet basic safety standards when intact but create significant liability exposure. The breakage risk means potential injuries from sharp edges. Modern B2B buyers prefer materials like food-grade stainless steel that eliminate these concerns while meeting all required certifications without the fragility issues.

The safety question goes beyond just breakage injuries. Glass can develop micro-cracks that aren't visible. These cracks can harbor bacteria. They can also cause sudden failure when the flask contains hot liquid. I've seen reports of glass bottles shattering from thermal shock. This happens when someone pours hot coffee into a cold glass vessel. Stainless steel doesn't have this problem. Our double-wall vacuum insulated bottles handle temperature differences without any risk.

Certification requirements have also evolved. My buyers need FDA approval. They need LFGB certification for European markets. They need to provide material safety data sheets. Stainless steel makes this straightforward. We use certified 304 or 316 grade steel. The material composition is consistent. The testing is standardized. With glass, especially glass-lined products, you need to certify both the glass interior and the outer shell. The complexity increases. The costs go up.

There's also the long-term safety aspect. A stainless steel bottle lasts for years with normal use. The material doesn't degrade. It doesn't develop weak points. A buyer can confidently brand it and expect it to represent their company well for a long time. Glass wears differently. The surface can get scratched. These scratches collect residue. They make cleaning harder. Eventually the glass looks old and worn even if it hasn't broken.

Conclusion

Glass-lined flasks fail on multiple practical dimensions. The breakage risk, packaging costs, and safety concerns make stainless steel the clear choice. I've built my business on materials that work reliably in real-world supply chains.